-

Les boulons fournis ont la longueur appropriée pour l'installation d'un treuil WINCHMAX de 13 500 lb sur une plaque de 5 à 7 mm. D'autres épaisseurs peuvent nécessiter des boulons de longueurs différentes. Les critères requis sont que les boulons soient d'au moins une résistance à la traction de grade 8,8, que la longueur du filetage soit suffisamment longue pour engager complètement l'écrou carré mais ne doit pas dépasser au point que le boulon entre en contact avec le haut du boîtier de l'écrou dans le cadre du treuil.

Veuillez lire le guide d'utilisation des boulons de montage sous l'onglet « Spécifications ».

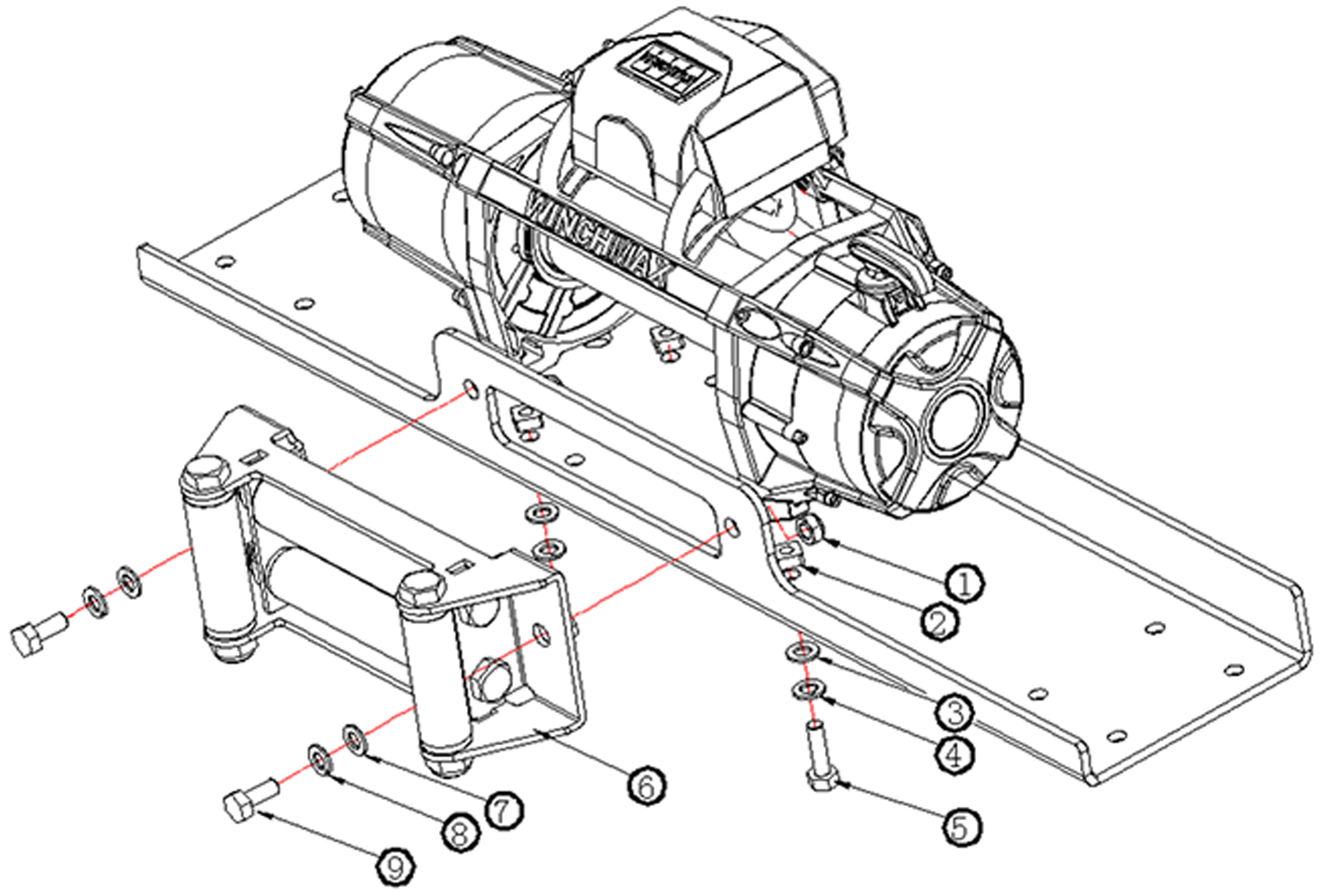

L'ensemble de boulons de montage de treuil 13500 comprend :

4 boulons hexagonaux M10x30 de qualité 8.8

4 écrous carrés M10 (15,8 mm x 15,8 mm x 8,3 mm)

4 rondelles plates M10 (2,0 mm d'épaisseur)

4 rondelles élastiques M10 (épaisseur 2,8 mm)

2 boulons hexagonaux M12x25 de grade 8.8

2 x écrous hexagonaux M12 de grade 8.8

2 rondelles plates M12 (2,0 mm d'épaisseur)

2 rondelles élastiques M12 (épaisseur 3,3 mm)

-

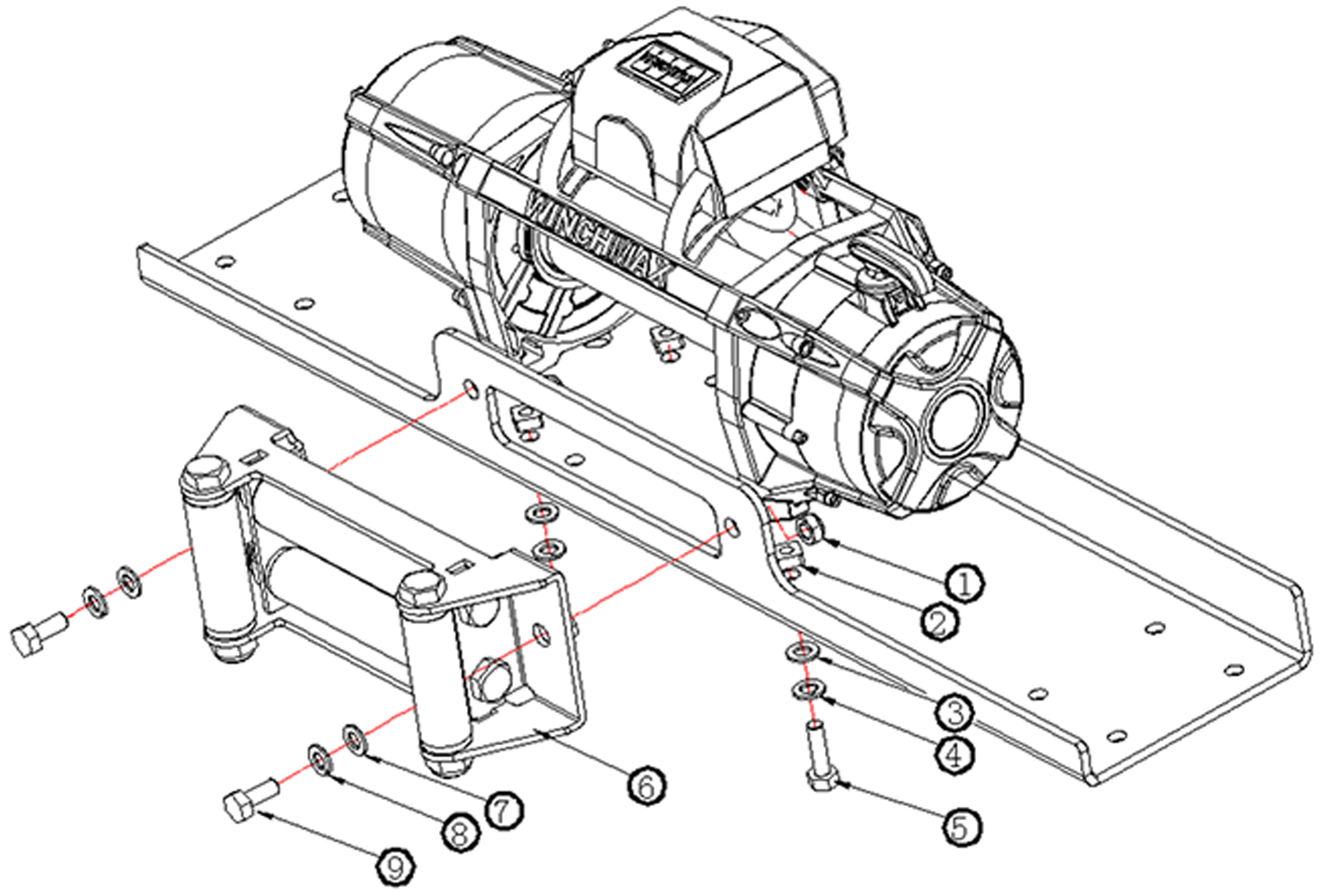

- Install a suitable mounting bumper or mounting plate in the required position. The winch must be mounted with the direction of pull perpendicular to the mounting bolt fixings. The plate should be fabricated from minimum 6mm steel.

- Attach fairlead (roller type for wire rope or aluminium hawse for synthetic rope) to the mounting plate using two hex nuts (9) & bolts (1) with flat (7) and spring (8) washers.

- Insert the four square nuts (2) into the pockets at the base of the winch frame.

- Thread the four high tensile bolts (5) with flat (3) and spring (4) washers up through the mounting plate and into the square nuts in the winch. Tighten the mounting bolts to a torque setting of 60Nm.

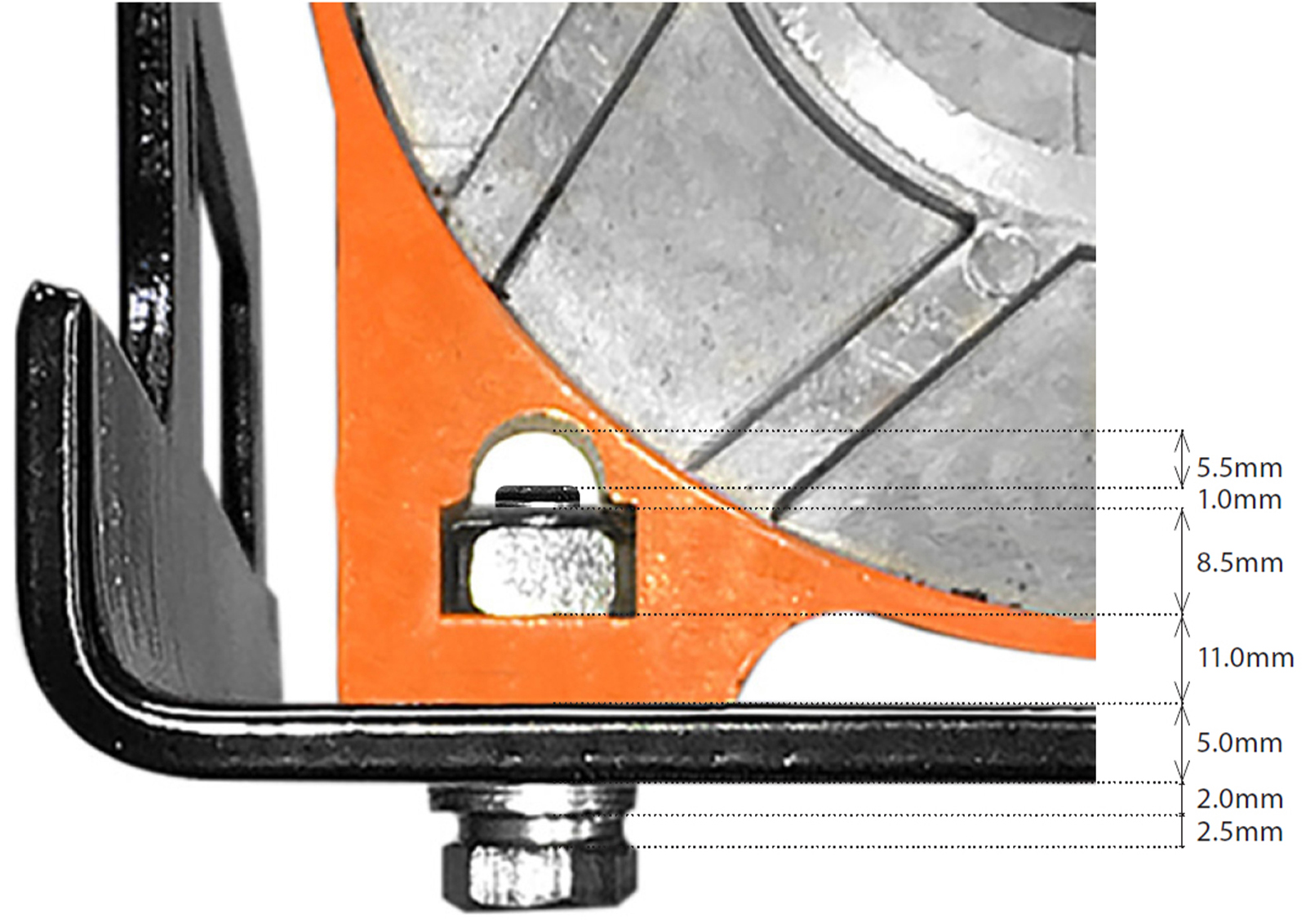

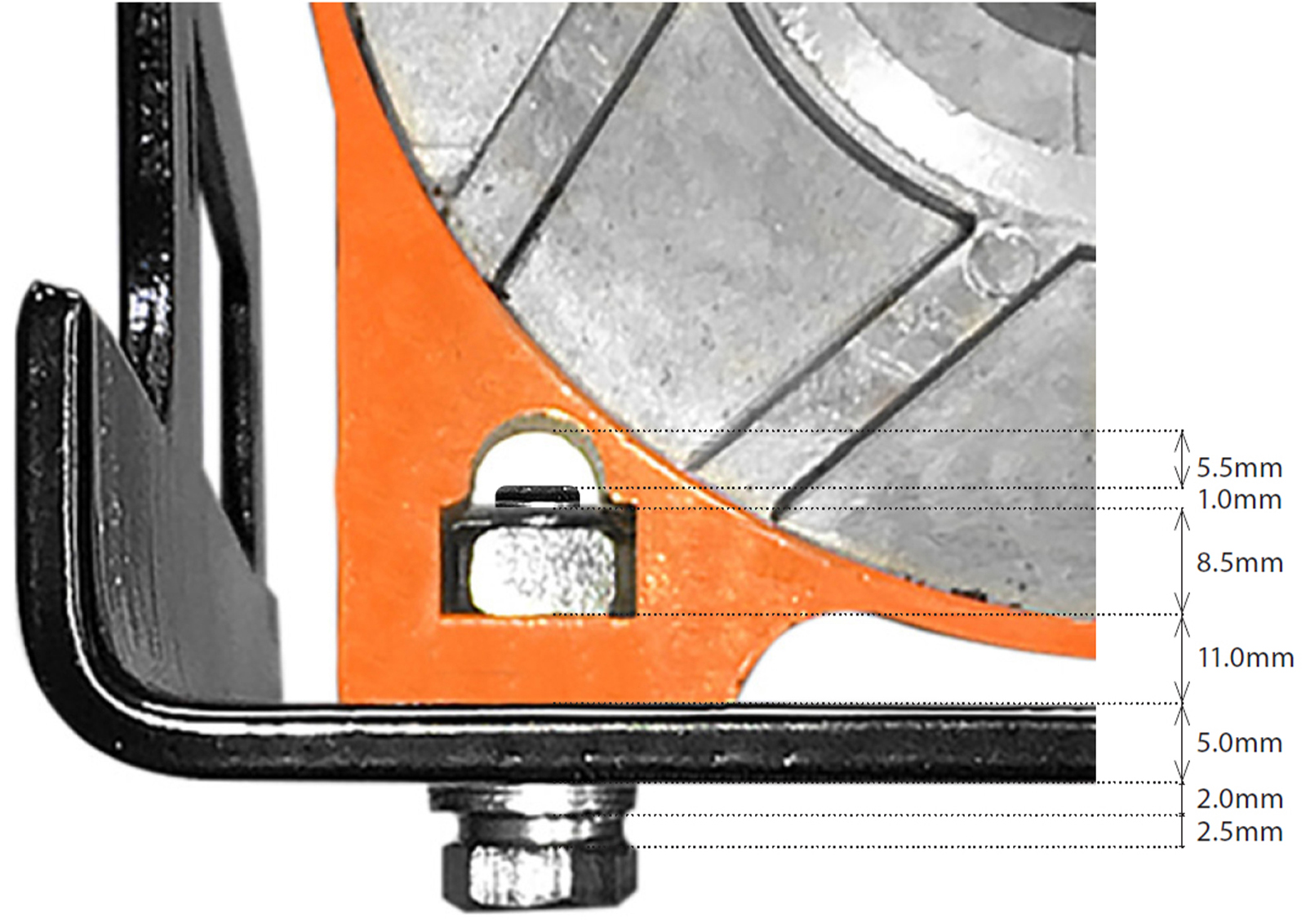

- The supplied bolts are the correct length for installation on a 5-7mm plate. Other thickness’s may require bolts of a different length. The required criteria are that the bolts are at least 8.8 grade high tensile, the thread length should be sufficiently long to fully engage the square nut but must not protrude to the extent that the bolt contacts the top of the nut housing in the winch frame.

- The mounting bolt must only be used with the correct square nut designed to seat into the nut pockets formed in each corner of the motor and gearbox base. Never use standard hexagonal type nuts.

- When selecting a bolt length the thread must be long enough to pass through the mounting material and fully fill the thread of the square nut without contacting the top of the mounting bolt pocket.

- The supplied flat washer and split lock washer should always be used.

- The minimum mounting bolt thread length = the thickness of the mounting material plus 24mm The maximum mounting bolt thread length = the thickness of the mounting material plus 29.5mm

- If you need to increase the clearance in the nut pocket, addition washers can be used but we do not recommend an increment of more than 4mm.

- Failing to correctly mount your winch could result in a catastrophic structural failure to the winch and serious consequential damage/injury.

-